AB Mauri

AB Mauri are a global enterprise specialising in bakery ingredients and other products.

Their factory in Hull produces yeast products supplying major baking and brewing companies in the UK. Producing yeast is a complex process, involving testing and recording of different production parameters at various stages. Mauri had developed a number of spreadsheets to monitor these figures, but these lacked integrated reporting and needing manually updating to reflect changing requirements of Mauri’s customers.

Solution

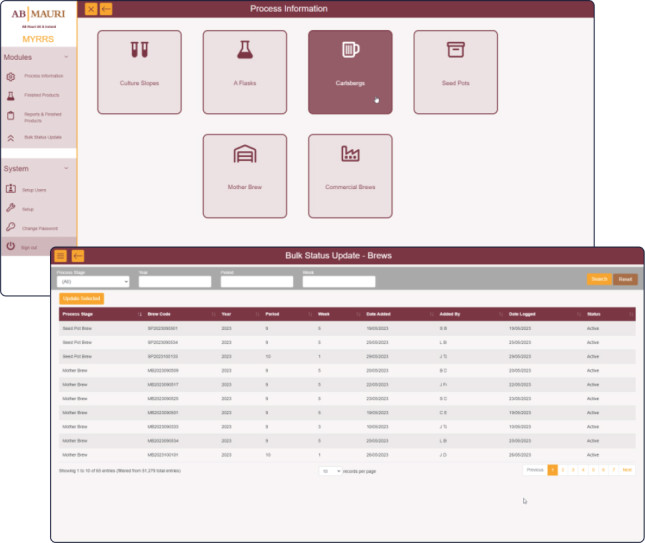

Intradev developed an integrated system called Mauri Yeast Results Reporting System or MYRSS. This system captures data throughout the production process and can generate various key quality reports and certificates of analysis for the products. The software was developed with an easy-to-use web-browser interface.

Benefits

Introduction of this system has allowed Mauri to generate the reports that it needs to effectively manage the business and easily generate custom certificates. It provides complete traceability of batches from finished products back to raw materials.

Our old systems recorded the data we needed but it was difficult to get an overall picture. We had to maintain the many different spreadsheets and databases to produce the reports we wanted. MYRRS has helped us to easily get the information that we need to manage the production process.

Certificates of Analysis are now much more easily produced, saving us time and improving accuracy. Our staff like the new system which is easy to use and maintain.

Rob Jenkins, Production Manager

.png)

Innovative technology that’s worth your investment

Whatever the size or complexity of your business, we can design a software solution to help drive efficiency improvements.